In layman's terms, its there to decrease deflection one would say. So "every ounce" of energy would go into the road.

I'd like to put some more insight into this.

All frames, whether steel, aluminum or carbon have a certain elasticity to them. This contributes to the comfort and "liveliness" of the bike. If they didn't, one is better off riding a bicycle made of reinforced concrete. Try a century on that one! Ouch...

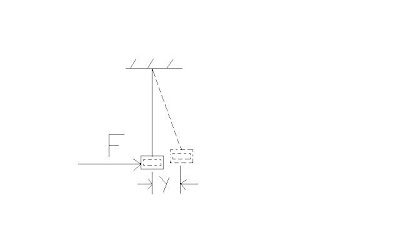

The external work done on an elastic member in deforming it is transformed into strain energy, or potential energy. If the member is deflected or deformed by distance y, this energy U is equal to the product of the average force, F and the deflection.

U = F.y

The above equation is general in the sense that F can also mean torque or moment.

Engineers would know where and how to find out formulas for F. This is gained through analysis of a bicycle bottom bracket. They draw free body diagrams, and pinpoint to the nature of the force(s), and the sites of loading.

Engineers would know where and how to find out formulas for F. This is gained through analysis of a bicycle bottom bracket. They draw free body diagrams, and pinpoint to the nature of the force(s), and the sites of loading.But in general, when those engineers come out with equations for U, it is generally found that

U is inversely proportional to a product of modulus of elasticity, and some form of area (in cases of torsion, there is a polar moment of inertia term). This modulus, a number characteristic of the material under consideration, is what is known as "stiffness"in layman's terms.

So, if 1 is inversely proportional to 2 (just to make things simple), a greater amount of 2 will lead to a lesser amount of 1.

Or, the development of high stress in the bottom bracket area of a bicycle with low modulus of elasticity and a low area or volume leads to a higher amount of strain energy storage. Do the opposite, and you have lesser strain energy storage.

Conservation of energy has it that energy created = energy destroyed. So this stored energy has to be released in some way when the loading is taken off. Some folks say all of that energy goes the drivetrain. Some say the frame springs back to its initial position. Others don't defend that theory and say most of it is converted to reactions in the muscles and heat and what not. These are the same ones who will complain about wet noodle like bottom brackets, and attribute to it losses of (outrageous!) 2-3 mph on their favorite climbs.

But the bottomline is, why do you want to bother yourself with all that if you can make a beefier, and stiffer bottom bracket through good design and appropriate material selection? The bottom bracket is then a more rigid point for pedal force delivery, and so, every "ounce" of energy can appropriately go to the tarmac.

Cool?

Interestingly, what bike companies don't tell you is that these numbers are very small. C'mon, we all know Keirin racers still use "flexy" steel and Merckx won most of his campaigns on the age old metal as well.

Hence, someone is making money off you. Otherwise they'd shut down and there'd be nothing new in the area of racing bicycles.

2 comments:

The new Madone highligts the 90mm bottom bracket. I guess they think they have it figured out.

It does make you wonder how many improvements can be made. Sure the car may drive itself one day... but we'll always push the pedals.

Merry Christmas! Donald The Daily Draft

Post a Comment